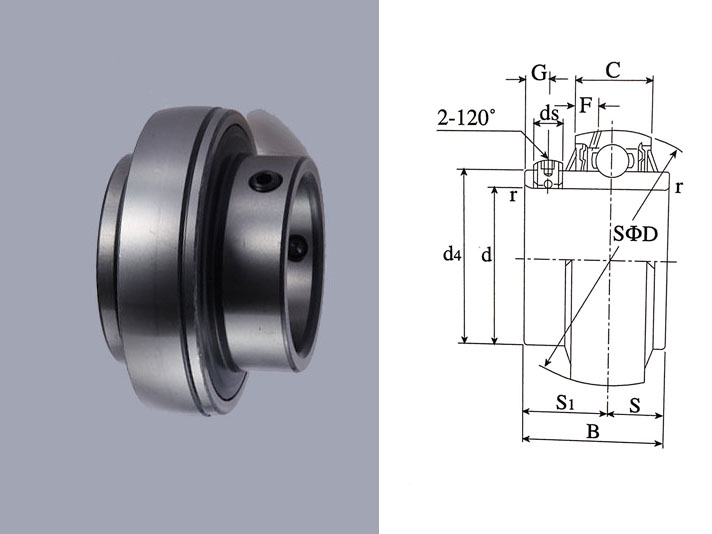

Overview of outer spherical ball bearing

The basic performance of the outer spherical bearing is similar to that of the deep groove ball bearing. However, because this kind of bearing is mostly used in rough machinery, the installation and positioning are not accurate enough, the alignment of the axis of the shaft and the seat hole is poor, or the shaft is long and the deflection is large, and the accuracy of the bearing itself is not high enough, and some structures are rough, Therefore, the actual performance of the same specifications of deep groove ball bearings to play a considerable discount. For example: the outer spherical ball bearing with jacking wire is applied to the through shaft with large deflection and stiffness difference. This kind of bearing has sealing rings on both sides, which can strictly prevent the invasion of dirt. It has been filled with an appropriate amount of lubricant when leaving the factory. It does not need to be cleaned or added with lubricant before installation. When the jacking screw on the protruding end of the bearing inner ring is fastened on the shaft, the allowable axial load shall not exceed 20% of the rated dynamic load.

Features of outer spherical ball bearing

The performance of the outer spherical ball bearing with eccentric sleeve is basically the same as that of the outer spherical ball bearing with jacking wire, but the jacking wire is not on the inner ring, but on the eccentric sleeve. The inner hole of the tapered hole outer spherical ball bearing is a tapered hole with a taper of 1:12, which can be directly installed on the tapered shaft, or installed on the shoulderless shaft with the help of the tightening bush, and the bearing clearance can be adjusted.

Applications of outer spherical ball bearings

Spherical bearings are preferred for applications requiring simple equipment and parts, such as agricultural machinery, transportation system or construction machinery.

It is mainly used to bear the combined radial and axial load with radial load as the main load. Generally, it is not suitable to bear the axial load alone. This kind of bearing can be installed with inner ring (with a full set of rollers and retainer) and outer ring respectively. This kind of bearing does not allow the shaft to tilt relative to the shell, which will produce additional axial force under radial load. When the axial clearance is too small, the temperature rise is higher; When the axial clearance is large, the bearing is easy to be damaged. Therefore, special attention should be paid to adjusting the axial clearance of the bearing during installation and operation. If necessary, pre interference installation can be used to increase the rigidity of the bearing.

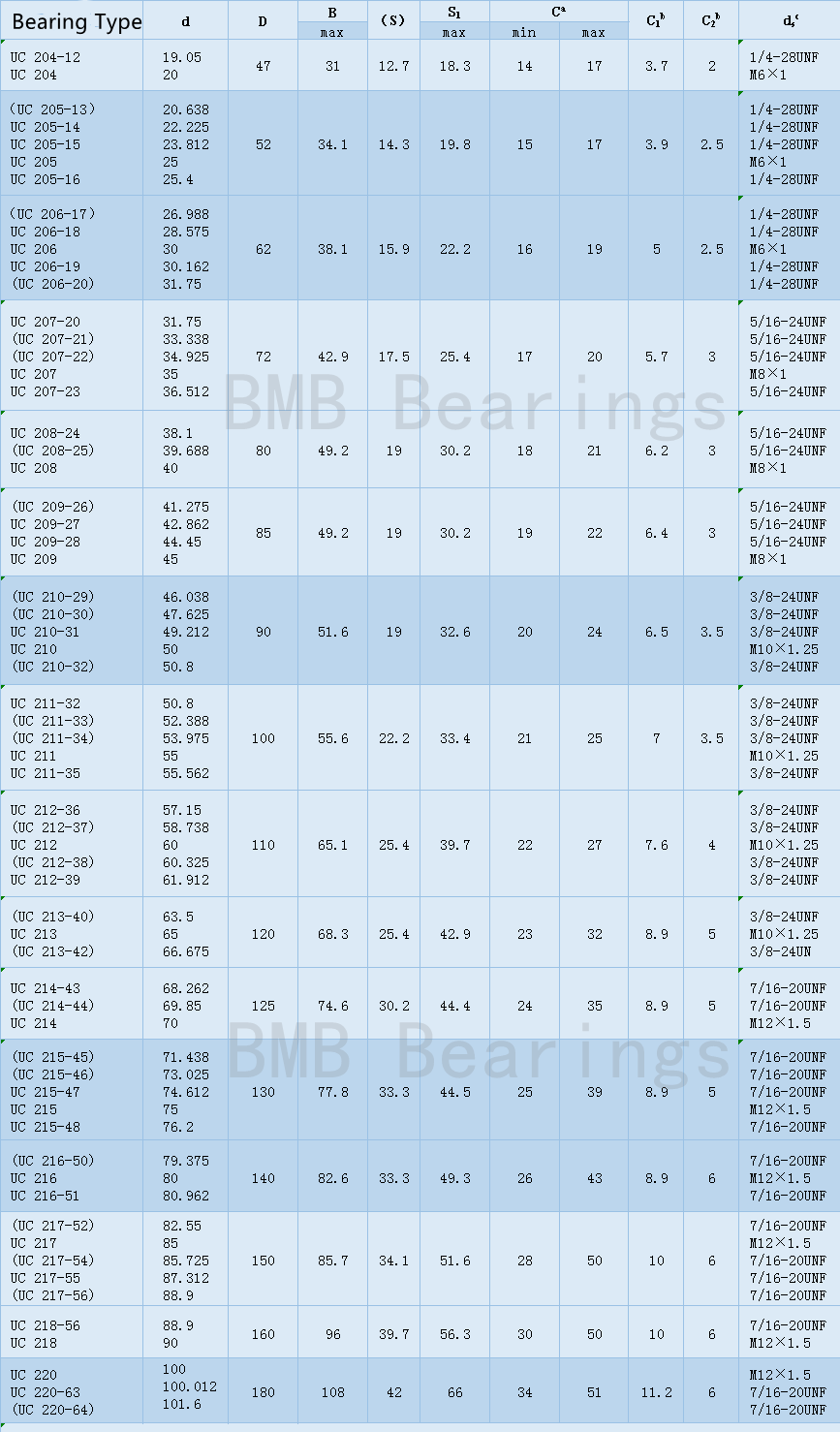

Bearing parameters

If you are looking for outer ball bearing with seat and know the latest price of outer ball bearing with seat, please contact us in time Get the latest price.

Ask a quote for the latest price and one of our team members will respond as soon as possible. Fields marked with * are required.